Contribution to SDGs

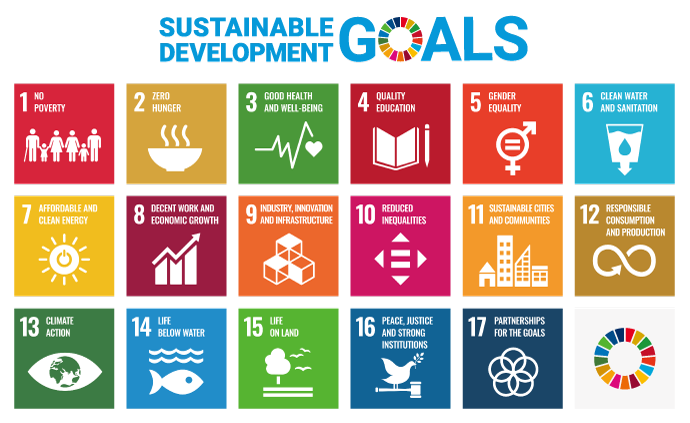

In September 2015, the United Nations launched the 17 Sustainable Development Goals (SDGs) for the 193 member states of them as a universal call to action to end poverty, protect the planet and ensure that all people enjoy peace and prosperity, by 2030.

Our inkjet technologies contribute to the following 10 goals.

|

|

|

|

|||||

|

|

|

|

|||||

|

|

Response to climate change (TCFD recommendations)

To manage the business impacts brought about by climate change, Mimaki Engineering strives for better and deeper disclosure based on the recommendations by TCFD, the Task Force on Climate-Related Financial Disclosure.

View our Basic Philosophy on Corporate Governance and Corporate Governance Report.

See Mimaki's climate-related strategy in the framework of TCFD.

See how Mimaki manages climate-related risks in the framework of TCFD.

See Mimaki's metrics and targets in the framework of TCFD.

An itiniative for resourse circulation by used PC donation

We have initiated a recycling program through donating our used PCs to the recycling business of "Ecofa Okaya," a designated disability welfare service facility located in Okaya City, Nagano Prefecture. For more information on Miimaki Ecofa Okaya, please click here.

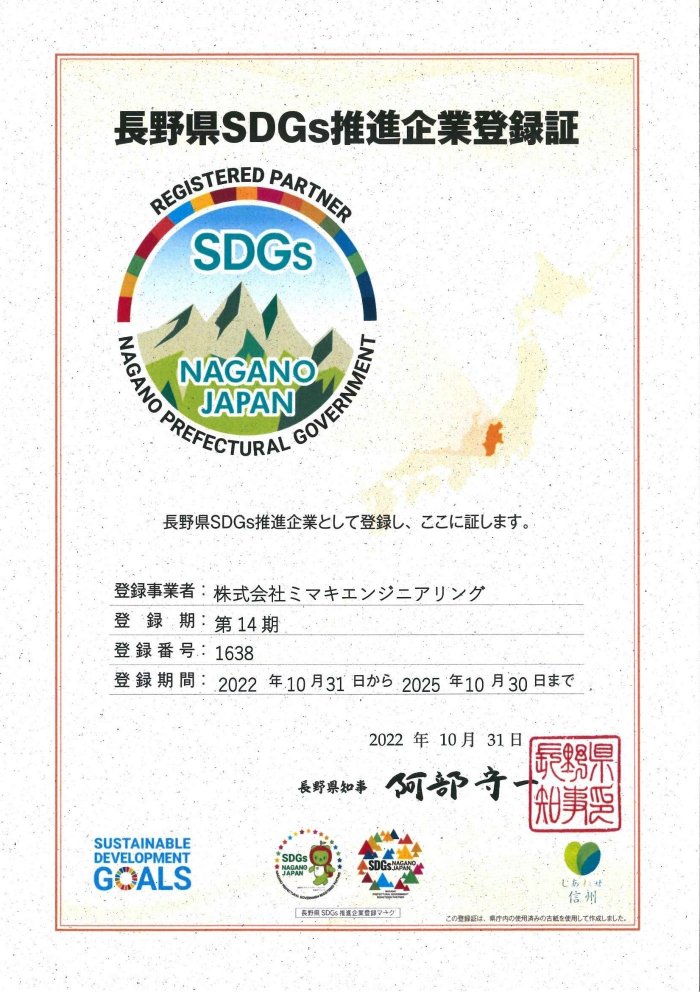

Registered as one of the 14th Nagano SDGs partner companies.

We have been working on resource conservation to help achieve a circular economy.

As part of this process, we have applied to and have been approved by the SDGs partnership conducted by Nagano prefecture, where our headquarter and major factories are located.

This partnership is aimed by Nagano prefecture to support local companies that utilize SDGs in their business strategy from the perspectives of environment, society, and economy.

Based on the requirement, we are going to regularly report our activities to Nagano prefecture. Through inspecting our contribution and initiating effective actions, we proceed with the business operation responding to the social and environmental needs.

The registration documents are as follows.

Declaration to achieve SDGs

Actions taken by SDGs company

Please be reminded that those documents are in Japanese.

Participated in the Foster parent promotion business of the forest

Recently, we have signed the "Foster parent of the forest Agreement" in order to collaborate on the "Nigiyaka Forest Project," which is being developed by the Nagano Josho Forest Certification Council in SGEC certified forests*.

*Forests that meet certain standards for sustainable forest management and environmental conservation considerations in a system in which independent third-party organizations conduct certification audits in accordance with international standards.

The "Nigiyaka Forest Project" as a forest conservation activity was decided to participate in this agreement because it is an activity that contributes to the community and welfare of employees, in addition to the forest and biodiversity conservation efforts that are indispensable for continuous corporate activities in the Jo-Sho area of Nagano Prefecture, where our head office and main plant are located.

With the conclusion of the Foster parent of the forest Agreement this time, we will further focus our efforts on global warming countermeasures, global environmental conservation, and contributions to the community through sustainable forest conservation activities.

September 22, 2022 Press Release "Participated in the Foster parent promotion business of the forest"(Japanese)

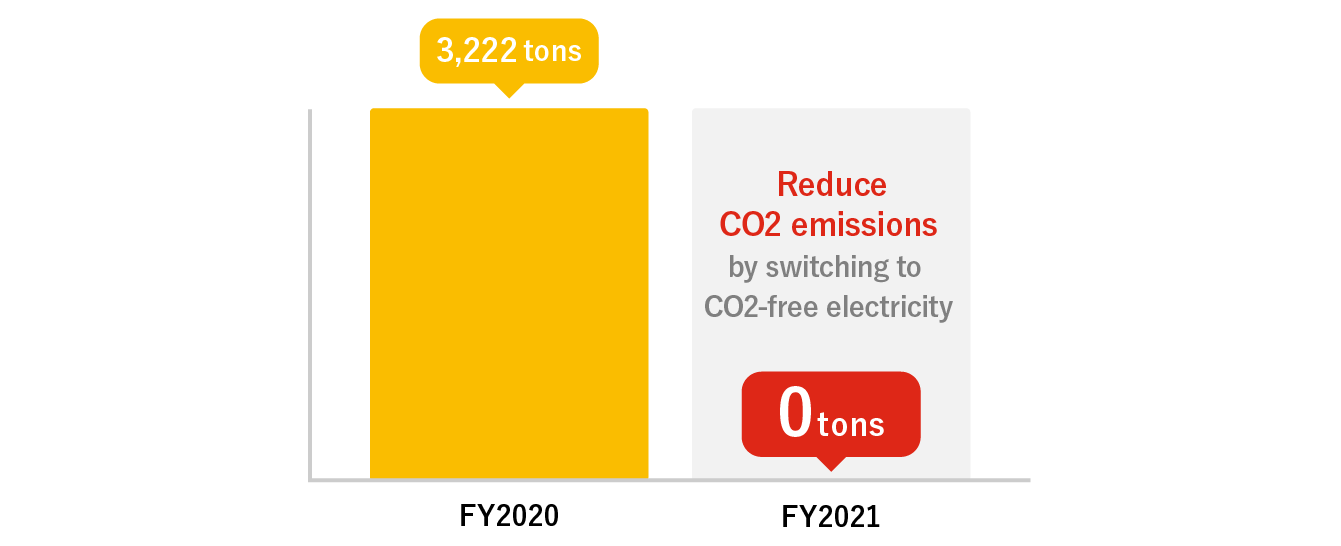

CO2-free electricity has been introduced.

We have been promoting the expansion of our digital on-demand printing business, which uses inkjet technology to contribute to social and environmental needs. In addition to these efforts, we have decided to introduce CO2 free electricity with the aim of contributing to solving environmental issues towards the realization of a decarbonized society.

We will continue to make efforts to improve the quality of our products and services. The new system is designed to reduce the amount of electricity used by the company's employees and to reduce the amount of CO2 emissions. (Actual results for 2020)

We commit to resource recycling management and technology, as part of complying with sustainability

Our group build resource recycling management system and technology, as part of complying with sustainability.

Until now, we have continued to expand the development of digital on-demand printing, which contributes to social and environmental needs, with our proprietary inkjet technology.

We will take advantage of the future digital transformation (which includes the digitalization of the value chain and leads to new added value), to quickly respond to societal and environmental needs that lead to higher added value, such as unattended operation/labor-saving, high speed, high image quality, and water-free printing.

Creating a sustainable society with developing digital on-demand printing

Using our proprietary raster technology and vector technology, we will drive the further development of digital on-demand printing.

Raster technology (for inkjets, etc.)

Vector technology (for cutting plotters, etc.)

Since they discharge ink only on the design portion, inkjet printers require only a small amount of ink to print.

They also eliminate the environmental impact of processing effluent from plate washing.

Our proprietary technology allows cutting out media (printed materials) with high accuracy.

We contribute to the protection of resources by eliminating wasteful printed materials through highly accurate cutting technology.

We will drive the further development of digital on-demand printing, contributes to social and environmental needs, with our proprietary raster technology and vector technology.

What is digital on-demand printing?

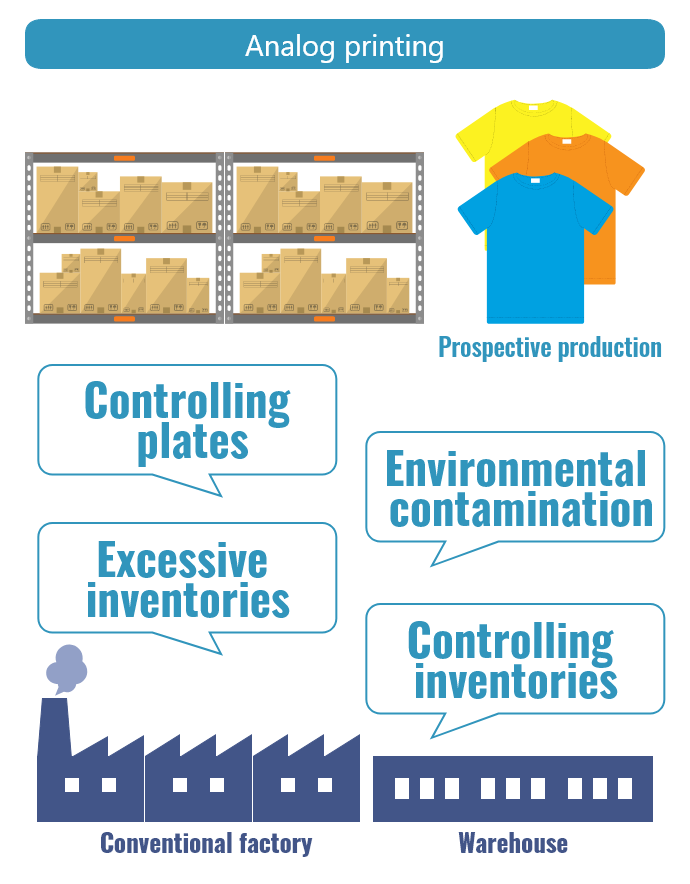

Analog printing

Analog printing needs the plates, there are concerns about environmental contamination caused by plate cleaning and equipment cleaning.

In addition, excessive inventories and inventory control occur because of prospective production.

Furthermore, they need a warehouse to control the plates used in printing and excessive inventories.

Digital on-demand printing

Digital on-demand printing system enables to print only necessary quantity and reduces excessive inventories.

Plate-less inkjet technology produces water-saving and low-waste printing.

The ability to set up clean working environments with space-saving equipment makes possible the production on peripheral cities, close to the point of consumption.

In addition, linking consuming and producing regions help to cut the time and costs for logistics.