The pollution of freshwater due to textile processing and dyeing

Freshwater in the Earth is said to be 2.5% of the total.

Of these, only 0.3% of the water can be directly consumed by us.

Global water shortages are not yet known to stop and are becoming an increasingly serious problem.

One of the reasons for this is the overuse of water in factories, and some research has shown that 20% of freshwater pollution is caused by textile processing and dyeing.

In particular, there is a large amount of surplus sludge in dyed and processed waste water. Moreover, there are 2 billion tons of dyed wastewater every day worldwide.

This amount of wastewater run into approximately 26 unites of Lake Biwa in Japan in one year.

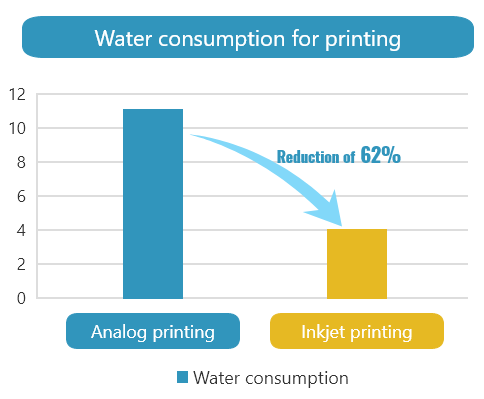

Reducing wastewater through inkjet printing

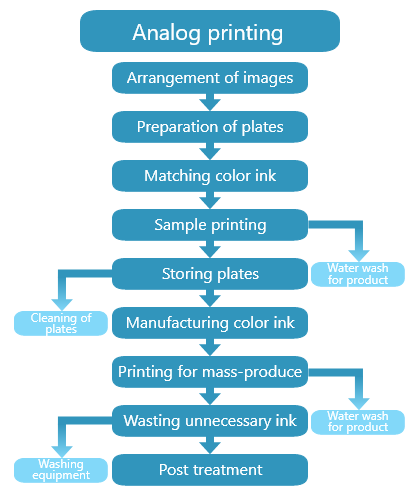

Analog printing

The feature of this system is that many of the printing processes, include arrangement of images, preparation of plates, matching color ink, sample printing, manufacturing color ink, printing for mass-produce, and post treatment process.

Wastewater generated in analog printing process

●Cleaning of plates after printing

●Water wash for product, which removes the surplus ink and pre-treatment agents

●Washing equipment

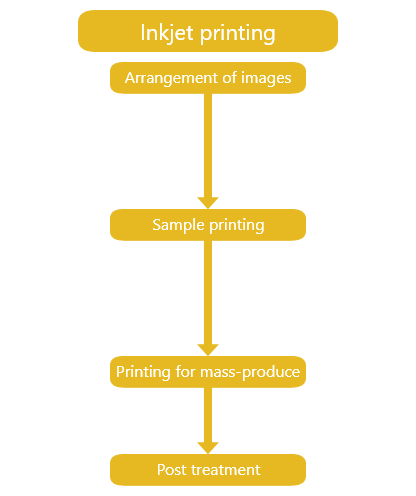

Inkjet printing

Inkjet printing is plate-less printing.

This reduces the environment burden by reducing the number of work procedures and eliminating the need for plate cleaning.

Inkjet printing can reduce water consumption by more than 60% compared to analog printing.

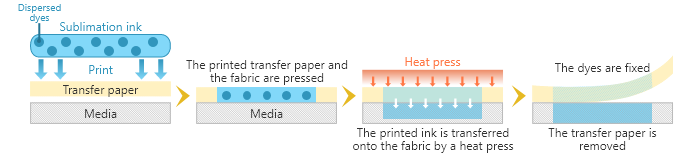

Saving water by sublimation printing

A sublimation printing is the method in which the transfer paper printed with dye sublimation ink is placed on the media and the two are pressed together at high temperature, and then transferred to it.

No wastewater is discharged and no dryers are required, because of water-free printing.

It is also a world-friendly printing technology that reduces the mass consumption of gases and electricity and CO2 emissions.